PROJECT CASES

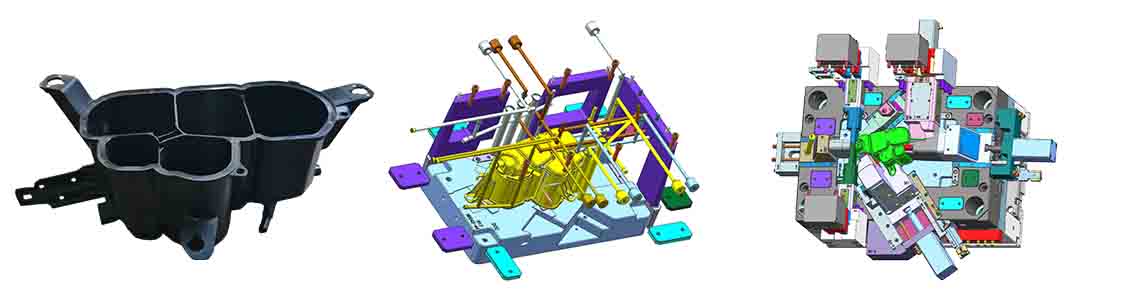

Auto Carbon Canister Mold

Customer Request

Automobile carbon canister mould, the product material is PA6+15GF-D122-G15.

The feature of this mould is that the slider molding area is very large, and when designing the slider, ejector pins or ejector blocks will be added to prevent the product from sticking to the slider;

Solution

This mould has large and numerous sliders, so it is necessary to design sufficient cooling lines to fully cool the sliders. At the same time, the reasonable mould opening sequence of the sliders will be considered, the parts with greater clamping force will be pulled out first, and then the whole part will be pulled out. This can control the deformation of the product; add the lifters in the slider, first pull out the undercuts in other directions, and then pull out the whole slider, so that the product can be demolded smoothly.

Result Feedback

The mould T2 trial is OK, fully reaching the state of mass production, and the mould is handed over to customer for mass production.