PRODUCT

Overmolding plastic injection molding

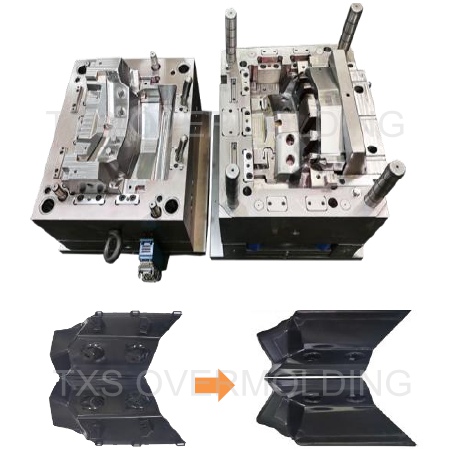

TXX provide guidance on the manufacturability of overmolding parts ready to be custom injection molding, or to create a mold design with the proper actions, gate locations, temperature control and venting.

Engineering and Technology-focused Personnel

Muiti Assist Aapabilities

Quality Control

Manufacturability Expertise

Innovative Mold Design

Process Flexibility

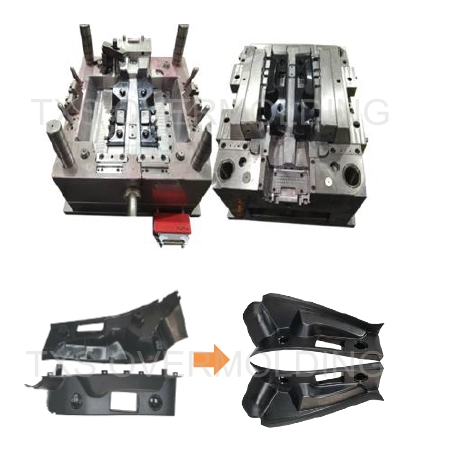

Overmolding Plastic Injection Molding

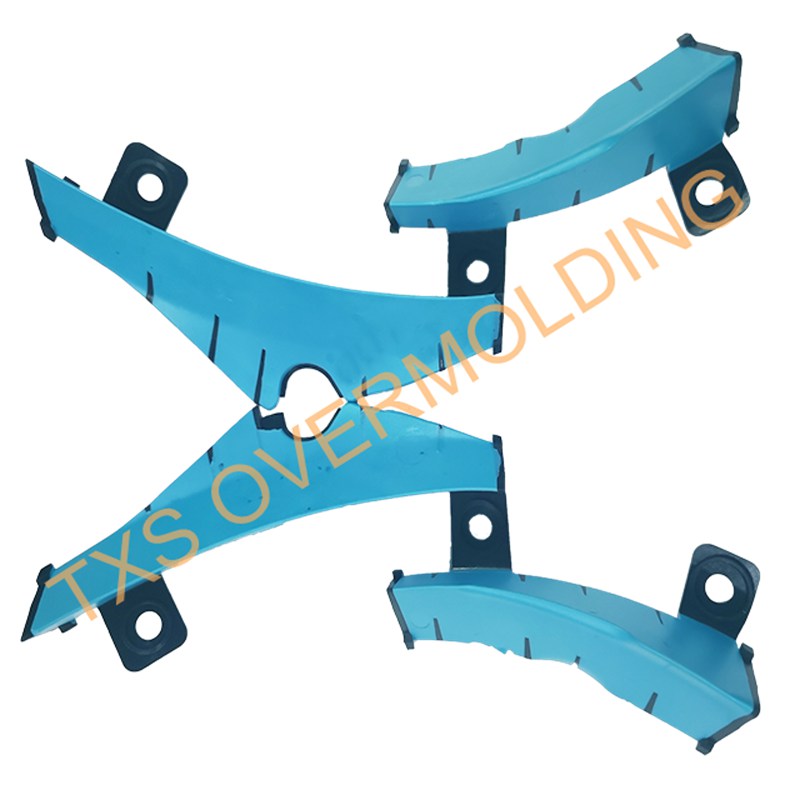

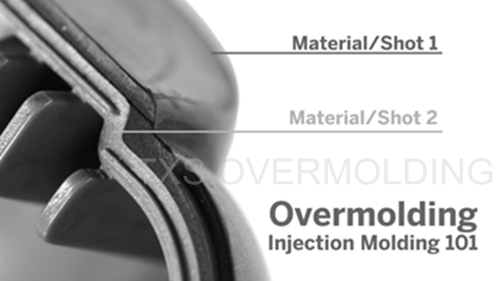

Plastic overmolding means to inject another plastic material over around an existing product, and then they will become one single unit.

This is very similar to insert molding method. The two material types from these two different operation can be different in plastic overmolding process.

The existing base product can be hard plastics like ABS or PP, and the secondary overmolding material can be soft material such like rubber.

This normally is used as the tools handle grips, knife handle grips and pens. And the colors can be different as well.

|

Product Name |

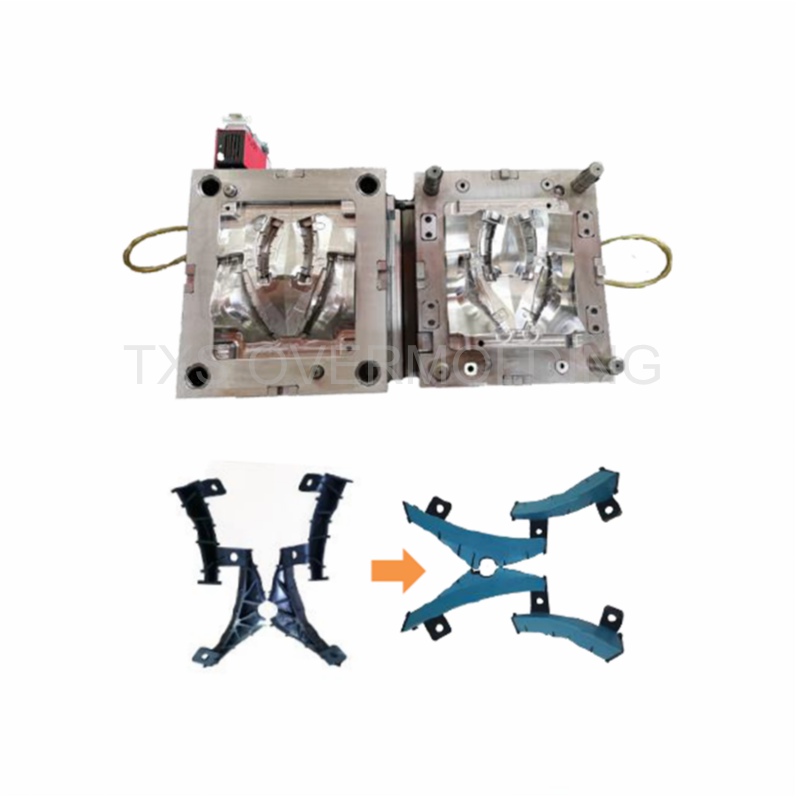

Overmolding-AUTO PARTS MOLD |

|

Cavity |

2 |

|

Runner |

Hot runner system,YUDO HRS |

|

Mold size & weight |

500*490*460mm&650KG |

|

Mold material |

Mold base material : A+B plate P20 Mold cavity material: S136 heat treatment HRC48-52 Cycle time :55s or so |

|

Mold shots |

1000K |

|

Product size |

210*160 |

|

Product material |

ABS+TPE |

Advantages of Plastic Overmolding:

1.Save cost and manufacturing time: If not using overmolding process, in order to bond two different materials together, an adhesive has to be used.

1.Save cost and manufacturing time: If not using overmolding process, in order to bond two different materials together, an adhesive has to be used.

By using the overmolding method, this secondary process can be eliminated.

2. Design benefits: Since the material types and colors can be different, the overmolding material can be soft and can be in a different color, to a certain extent,

this can be the decoration to the parts, so that the design will be better off.

Welcome visit our injection mold manufacturer factory.If you have further requirement for precision OVERMOLDING