PRODUCT

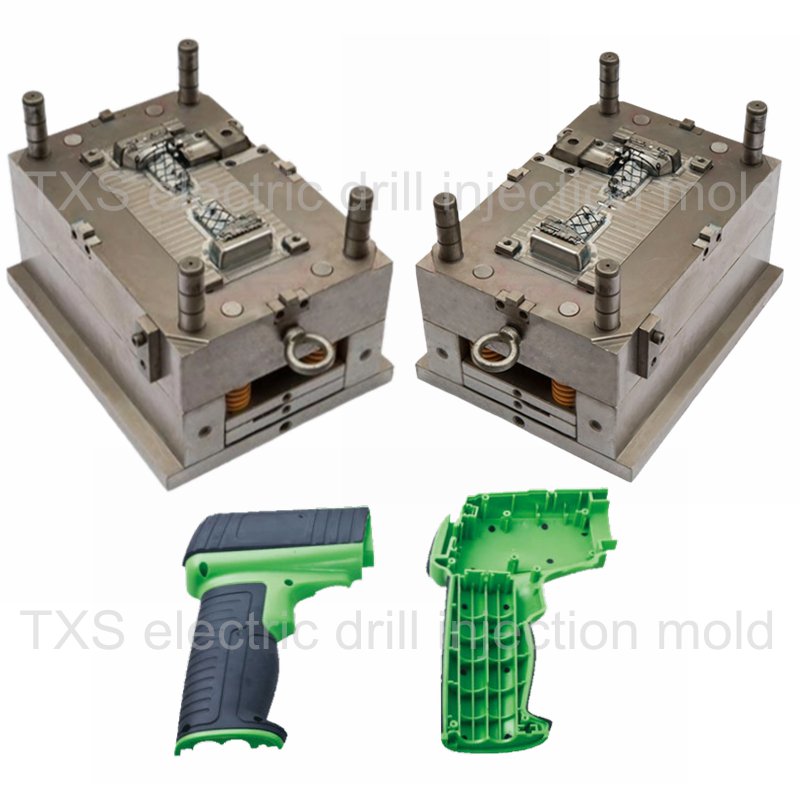

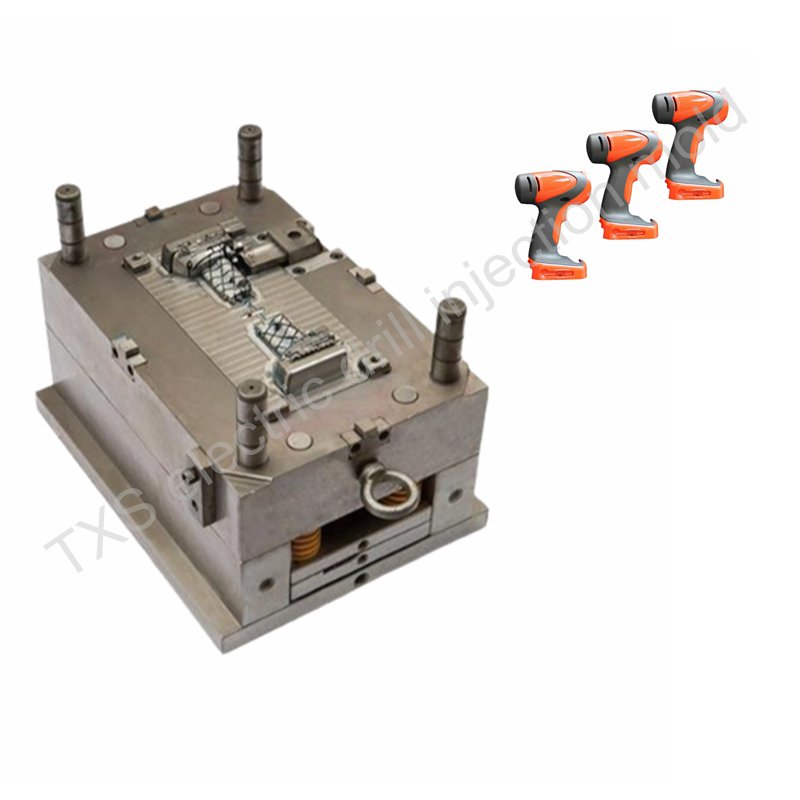

Precision electric drill housing plastic injection mold

Precision electric drill housing plastic injection mold

1+1 cavity design

1.2738 steel material

1 million mold shots

Precision electric drill housing plastic injection mold

TIANJIN XINXIANG injection mold factory design and making the electric drill housing plastic injection mold.

2K molding process adopt in the mold design and molding prodution.

Improve the touch feeling and save costs.

| Product Name |

Precision electric drill housing plastic injection mold |

| Plastic Material | PPR,PP, PP+GF, PP+ TALC,PE,ABS,POM,PPH…etc. PC, PS, PMMA for Transparent. |

| Steel of Cavity & Core | Buderus: 1.2311, 1.2738, 1.2344, 1.2316, BPM-HH, SUS-420…etc. Finkl: P20, HiP-20, H13…etc. Hitach: NAK80, DAC, FDAC, SKD61…etc. Assab: 618, 718, STAVAX…etc. |

| Steel of Mold Base | Commonly used material is S50C. |

| No. of Cavity | Customized (1+1) |

| Hardness of Cavity & Core | Heat Treatment Steel: HRC 48~52± 1° |

| Core pull or Ejection | Commonly used : Motor, oil cylinder, stripping plate, angel pin, ejector pin…etc |

| Cooling | In Core: Baffle or By pass cooling In Cavity Plate: Chain drilling type cooling |

| Surface Finish | Commonly used: Texture Hatching, EDM Hatching, Polishing, Diamond Polishing…etc. |

| Mold Lifetime | Commonly used: 300,000 ~ 500,000 shots or 1 year under normal use procedure for Pre-Hardness material. 1,000,000 shots or 1 year under normal use procedure for Heat Treatment material. |

| Runner | 1. Cold Runner. 2. Hot Runner. |

| Delivery time | Depends on the product size and complication. For First trial: 45 ~ 80 days after mold drawings approved. |

| Packing | Standard Wooden Box |

Welcome visit our factory, if you have further requirement for electric drill injection mold