PRODUCT

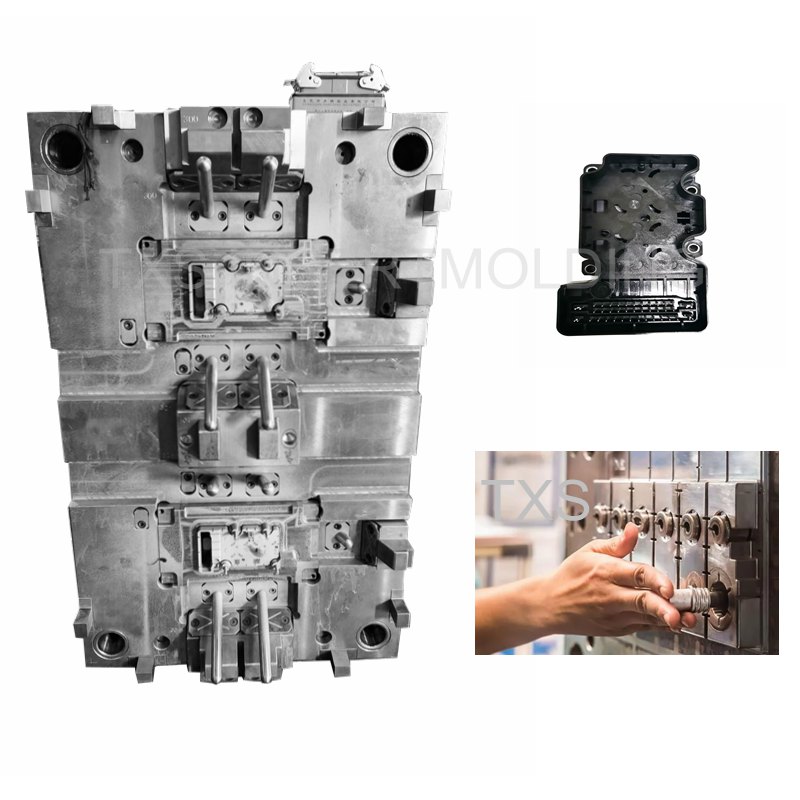

Insertmolding plastic insert molding

TXS Insertmolding for ABS ECU part injection mold adopt PBT+GF30 plastic material

So we use YUDO hot runner system for PBT material

1*2 cavity layout

Polishing surface treatment

Insertmolding Plastic Insert Molding

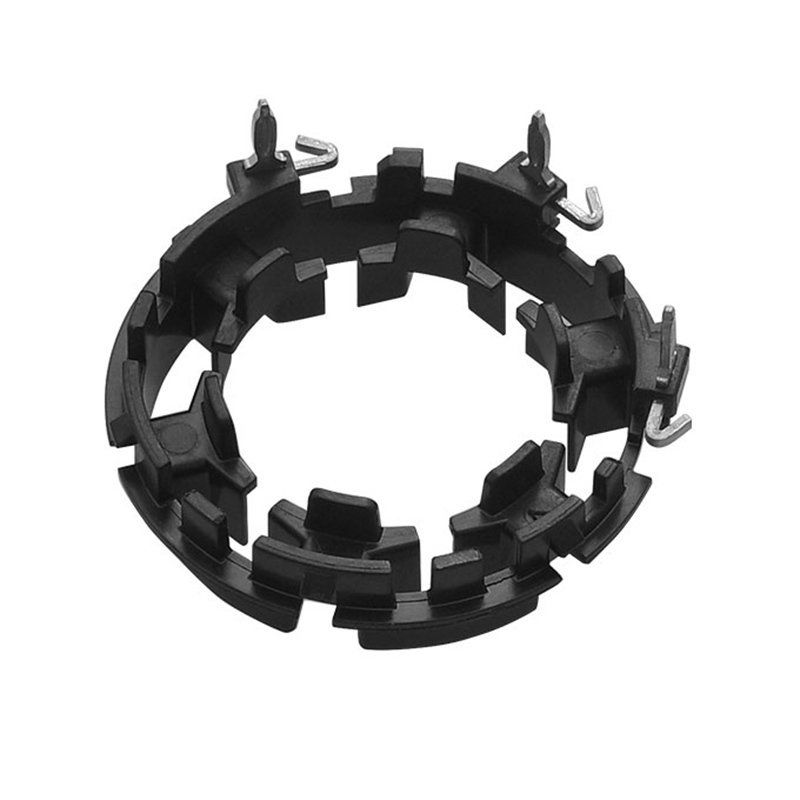

Insert injection molding is a injection molding process that with start placing metal into the mold, then the mold cavities filled with molten plastic. Once the plastic has cooled, the inserted parts are firmly bound to, and integrated into, the plastic parts.

Inserts can be steel, screw brass, magnets, Aluminum, or just about any substance that can withstand injection molding process.

|

Product Name |

Insertmolding-AUTO ABS ECU PARTS MOLD |

|

Cavity |

1*2 |

|

Runner |

Hot runner system,YUDO HRS |

|

Mold size & weight |

800*690*660mm&1250KG |

|

Mold material |

Mold base material : A+B plate P20 Mold cavity material: 8407 heat treatment HRC48-52 Cycle time :75s or so 280T injection machine |

|

Mold shots |

1000K |

|

Product size |

125.7X77.8X38.9 |

|

Product material |

PBT+GF30 |

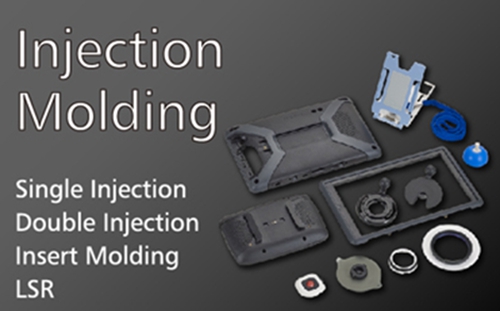

Advantages of Insert Molding:

Advantages of Insert Molding:

Lower Assembly Cost

Reduced Weight and Size

Improved Component Reliability

Improved Part Strength and Structure

Increasing Design Flexibility

Improved Part Quality Probability

Improved Production Efficiency

Welcome visit our factory, if you have further requirement for auto parts mold by insertmolding process