PRODUCT

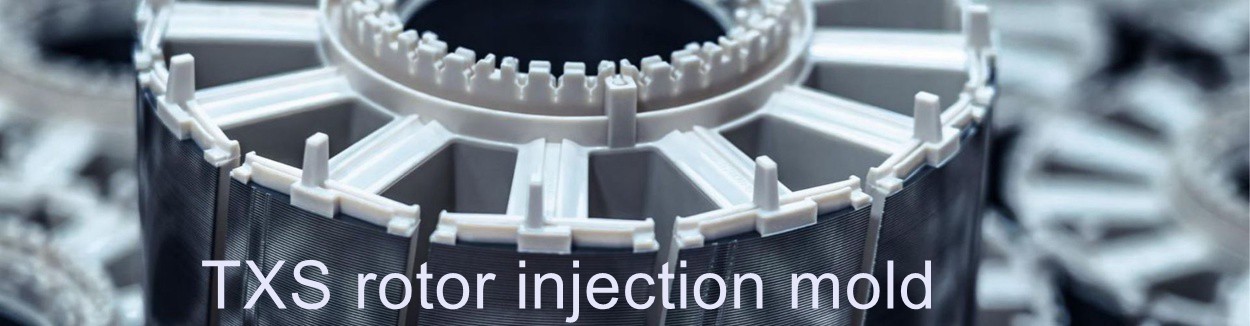

Precision rotor injection mold plastic parts PBT molding

Adopt plastic PBT injection molding-insertmolding processing for rotor injection mold.

PBT+GF30 plastic raw material with low liquidity,so we choose vavle type hot runner system.

Better for control mold temperature.

Precision rotor injection mold plastic parts PBT molding

The idea in rotor injection mold-insert molding is that one part or piece is specifically manufactured to fit inside a larger injection molding design, as an inner piece or component.

So the original part or “insert” is handed over to another assembly space, and it gets integrated into the bigger PBT injection molded component.

The plastic molding flows around the original piece to encapsulate or connect with it in some way. The finished product is composed of that original piece,

or multiple pieces, precision molded into the larger plastic product.

TXS focus on auto window lift rotor&stator mold design and manufacturer.

Supply PBT precision plastic parts service by insertmolding processing.

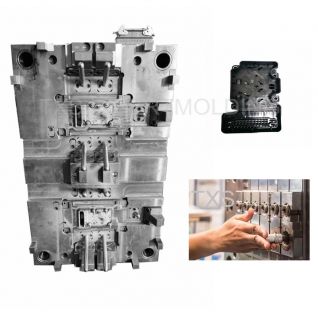

Please check the following list for the motor rotor injection mold details:

|

Product Name |

Insertmolding rotor injection mold(AUDI) |

|

Cavity |

4 |

|

Runner |

Hot runner system,vavle type |

|

Mold size & weight |

510*520*430mm&700KG |

|

Mold material |

Mold base material : A+B plate P20 Mold cavity material: 1.2344 heat treatment HRC48-52 Cycle time :45s or so |

|

Mold shots |

1000K |

|

Product size |

D30*25 |

|

Product material |

PBT-GF30 |

The INSERTMOLDING technology is applied to the injection molding of the rotor injection mold.

For this raw material-PBT+GF30,we choose vavle type hot runner system and easy control temperature.

Precision plastic injection moulding can ensure the motor quality and performance.

INSERTMOLDING PROCESSING:

Put a steel motor in the mold in advance then make precision plastic pbt injection molding.

Welcome visit our factory, if you have further requirement for insertmolding rotor injection mold